Washed Processing of Coffee: A Simple Guide

Washed (or wet) processing, is a widely used method to prepare coffee beans. This technique highlights clean and bright flavours, making it a favourite among many coffee producers. In this article, we’ll explore why coffee producers developed wet processing, its environmental impacts, and how it differs across regions.

The Origins of Wet Processing

Washed processing didn’t start as the first method for processing coffee. Initially, early coffee producers dried the whole cherry before removing the bean, using a method known as dry processing. Over time, wet processing became a better alternative, especially in humid regions where drying whole cherries posed challenges.

Why Use Washed Processing?

Washed processing enhances the clarity and brightness of coffee flavours. By removing the pulp before drying, this method reduces the risk of unwanted fermentation, which can negatively affect the taste. As a result, coffee processed with this method offers a cleaner, more consistent flavour profile, with brighter acidity and a lighter body compared to naturally processed coffee.

Environmental Impacts

Washed processing consumes a significant amount of water. In regions with limited water resources, this presents a major concern. The process washes the beans to remove the pulp, producing wastewater known as “honey water.” If producers fail to treat this wastewater before releasing it into local water sources, it can harm the environment. Consequently, the wastewater’s acidity and organic content can damage aquatic life and negatively impact communities that rely on these water sources.

To address these environmental concerns, some coffee producers are adopting more sustainable practices. For example, they recycle water, use machines that require less water, and treat wastewater before releasing it back into the environment.

Regional Differences in Wet Processing

Washed processing methods vary across different coffee-growing regions, influenced by local climate, water availability, and cultural practices. In Central America, for instance, producers pulp coffee cherries on the same day they’re harvested, and the beans ferment in water tanks for 12 to 24 hours. In contrast, the fermentation process in Ethiopia may take longer due to cooler temperatures.

Washed Processing in Brazil

In contrast, Brazil, known for its large-scale coffee production, often uses mechanical methods to speed up the wet processing process. These machines efficiently remove the mucilage without needing traditional fermentation. This method is popular in Brazil because it increases efficiency and allows for the processing of larger quantities of coffee.

Changes in Popularity

Washed processing gained popularity in the 19th century and remains a key method for producing high-quality coffee. However, in recent years, interest in natural and honey processing methods has grown. These methods create unique flavour profiles and are considered more environmentally friendly.

Despite this shift, many producers still prefer wet processing, especially those who seek a bright and clean cup of coffee. Additionally, some modern variations, such as the semi-washed or pulped natural process, combine elements of both wet and dry processing to create new and interesting flavours.

The Washed Processing Method: Step-by-Step

Harvesting: Farmers handpick coffee cherries when they are fully ripe.

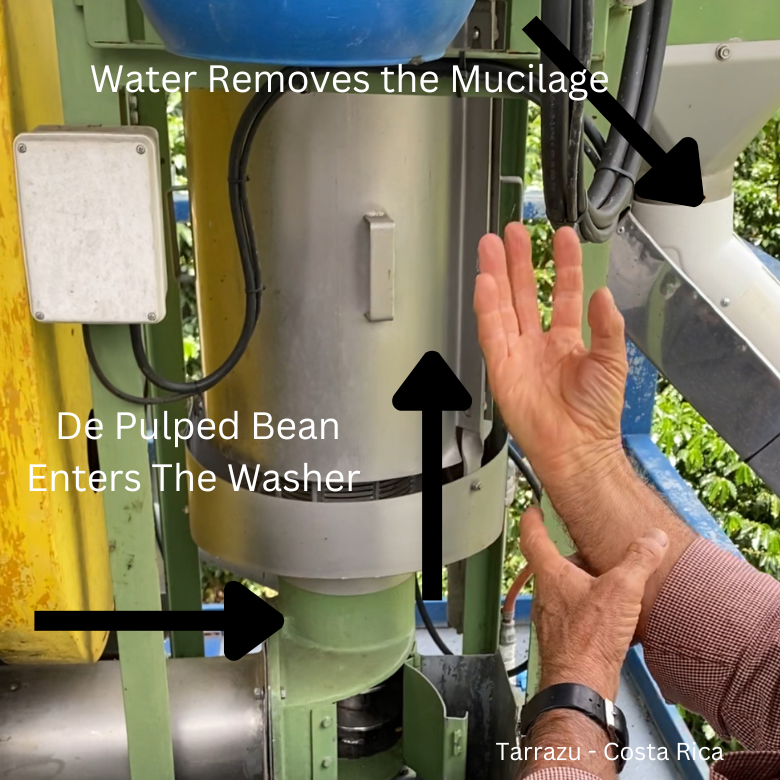

Pulping: A machine removes the outer skin and most of the fruit pulp.

Fermentation: The beans, still covered in a sticky layer called mucilage, ferment in tanks. This process breaks down the mucilage.

Washing: After fermentation, producers wash the beans to remove any remaining mucilage.

Drying: The clean beans, now called parchment coffee, dry in the sun or in mechanical dryers until they reach the right moisture level.

Hulling: Machines hull the dried beans to remove the parchment layer, revealing the green coffee beans inside. These beans are then ready for export or further processing.

Conclusion

In conclusion, washed processing has played a crucial role in the coffee industry, offering a method to produce coffee with clean, bright flavours. While the method presents environmental challenges, advancements in technology and sustainable practices help reduce these effects. As a result, the coffee industry continues to evolve, and wet processing remains a key method for producing consistent, high-quality coffee that delights coffee enthusiasts around the world.

0 Comments